Sandblasting is an effective and versatile cleaning technique to eliminate dirt, rust, paint or anything left on the surface of different materials like metal, concrete, glass, wood, stone, etc. To proceed with this method, we send a high-pressure blast of sand or garnets on the surface to clean. The abrasive force removes the top layers of the surface, leaving it clean and ready to work with.

Sandblasting is used in a number of industries like aeronautics, shipbuilding, building restoration, manufacturing of machines and heavy equipment, etc. More specifically at Desforges, we have a 12 x 12 x 24 pi sandblasting room that allows us to clean the surface of larger parts.

To find out more about our comprehensive sandblasting services to suit your needs, don’t hesitate to contact us!

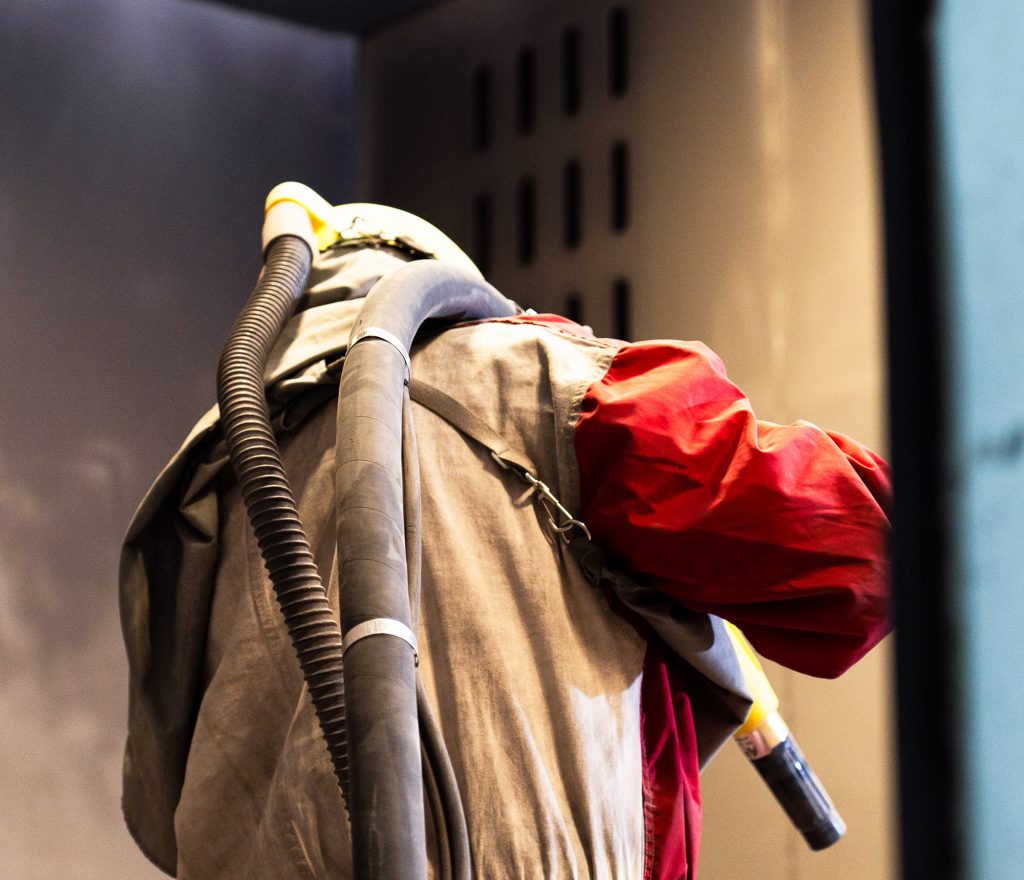

A source of compressed air, a tank of abrasive material, a sandblasting nozzle, a pressure control system and personal protective equipment for the workers are the equipment required for sandblasting. The air compressors provide the compressed air required to shoot the abrasive product, whereas the tank of abrasive stores the abrasive product and consistently supply the nozzle. There are different sizes and shapes of nozzles for a wide range of sandblasting uses. The pressure control system regulates the speed and pressure of the blast of abrasive material.

There is a variety of abrasive material that can be used to sandblast: sand, garnets, sodium bicarbonate, recycled glass, etc. Each abrasive material has its own qualities and specific uses. For example, sand is mostly used to clean concrete or stone, whereas garnets are more effective to clean rust or paint from metal surfaces.

At Desforges, when your project is a smaller or more fragile part, we use a chemical cleaning treatment. We choose the best option for your alloy to make sure of the readiness of the surface. One of these options, among others, is a five-stage cleaning system.

Sandblasting has many advantages when compared to other cleaning methods. First of all, sandblasting is very effective to clean dirt and anything left on the surface, even in areas that are difficult to reach. Moreover, sandblasting may be used on a variety of surfaces, so it is versatile. Last, sandblasting is well known for being efficient and quick, which reduces lost time in many industries.

As previously mentioned, sandblasting is done with different abrasive materials depending on the surface to clean. It is used for many industrial and commercial purposes. For example, it may be used to prepare a surface to paint or to remove old paint and rust to restore historic buildings.

Sandblasting is also used in manufacturing machines and heavy equipment to clean the parts and remove residues on the surface that could affect the performance. In the marine industrie, sandblasting is used to clean the ship hull and remove any sea debris that could impact the ship’s performance.

Finally, sandblasting is used in aeronautics to clean the planes’ engines and remove anything left on the surface that could reduce efficiency.

Sandblasting can be dangerous if not performed correctly. It is important to hire a professional to protect the project holders. Workers must wear personal protective equipment such as safety glasses, breathing masks, gloves and protective clothing.

In addition, proper airflow is necessary to avoid breathing dust and dangerous smoke. The workers must have been trained appropriately in safety measures and sandblasting techniques, all of this to ensure that the risks of accidents are greatly reduced.

Discover how our precision sandblasting techniques can revitalise your surfaces. Contact us today for a tailored quote

Take advantage of a turnkey painting service.

ISO 9001 certified.

Listening and availability at a higher level.